Back

Advanced Materials and Manufacturing

It’s getting hot in here: lasers deliver powerful shocking punch

Shock experiments are widely used to understand the mechanical and electronic properties of matter under extreme conditions, like planetary impacts by meteorites. However, after the shock occurs, a clear description of the post-shock thermal state and its impacts on material properties is still lacking. Lawrence Livermore National Laboratory (LLNL) scientists used ultra…

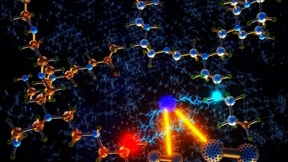

Molecules get a boost from metallic carbon nanotubes

A Lawrence Livermore National Laboratory (LLNL) team has found that pure metallic carbon nanotubes are best at transporting molecules. Molecule separations play an ever-increasing role in modern technology from water desalination to harvesting critical materials to high-value chemicals and pharmaceuticals manufacturing. To enhance water and proton transport, LLNL…

Chemical and transportation industries could get a boost with new catalyst coating

Coupling electrochemical conversion of the greenhouse gas CO2 with renewable electricity sources — such as solar and wind — promises green production of high-demand chemicals and transportation fuels. Carbon dioxide coupling products such as ethylene, ethanol and acetic acid are particularly useful as feedstocks for the chemical industry and powering vehicles. While…

Signal and image science community comes together for annual workshop

Nearly 150 members of the signal and image science community recently came together to discuss the latest advances in the field and connect with colleagues, friends and potential collaborators at the 28th annual Center for Advanced Image and Signal Science (CASIS) workshop. Held at the University of California Livermore Collaboration Center (UCLCC) for the first time, the…

DOE, LLNL take center stage at inaugural artificial-intelligence expo

Lawrence Livermore National Laboratory (LLNL) Director Kim Budil and other LLNL staff joined Department of Energy (DOE) Deputy Secretary David Turk, National Nuclear Security Administration (NNSA) Administrator Jill Hruby, DOE Under Secretary for Science and Innovation Geraldine Richmond, DOE Director of the Office of Critical and Emerging Technologies Helena Fu, U.S…

Manufacturing optimized designs for high explosives

When materials are subjected to extreme environments, they face the risk of mixing together. This mixing may result in hydrodynamic instabilities, yielding undesirable side effects. Such instabilities present a grand challenge across multiple disciplines, especially in astrophysics, combustion and shaped charges — a device used to focus the energy of a detonating explosive…

LLNL hosts Early Career Information Day focused on advanced materials and manufacturing

The University of California (UC) and Lawrence Livermore National Laboratory (LLNL) have a storied history going back to the founding of the Laboratory in 1952. The work conducted at the Lab since that time has benefited in many areas from successful collaboration with researchers and contributors within the UC system. In the spirit of continued collaboration, a UC Early…

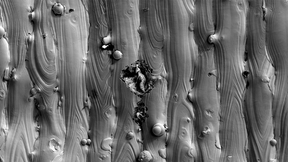

LLNL researchers uncover culprits behind pitting corrosion in 3D-printed stainless steel

Like a hidden enemy, pitting corrosion attacks metal surfaces, making it difficult to detect and control. This type of corrosion, primarily caused by prolonged contact with seawater in nature, is especially problematic for naval vessels. In a recent paper published in Nature Communications, Lawrence Livermore National Laboratory (LLNL) scientists delved into the mysterious…

LLNL’s elite Machinist Apprenticeship Program to begin accepting applications for 2024

Looking to advance your career in machining? The annual job posting for Lawrence Livermore National Laboratory’s (LLNL’s) esteemed machinist apprenticeship will go live in January and will accept applications for approximately one month. The California-certified program is one of the oldest in the nation, and one of the most unique. Apprentices are trained in LLNL’s…

Probing the temperature of materials under extreme pressure

In new experiments at Lawrence Livermore National Laboratory’s National Ignition Facility, scientists measured the extended X-ray absorption fine structure (EXAFS) of copper to probe its temperature under extreme pressure. The research appears in the journal Nature Communications. Dynamic compression experiments at high-energy-density laser facilities have expanded the…

LLNL hosts HBCU students, faculty to build new pipeline of talent

For the second consecutive year, Lawrence Livermore National Laboratory (LLNL) hosted a group of student scholars and faculty members from Historically Black Colleges and Universities (HBCUs) on a recent five-day visit. LLNL’s goal is to develop the next wave of summer interns — and to build a strong pipeline of talent — from historically marginalized groups in science,…

LLNL’s Feaster named to American Institute for Chemical Engineering’s '35 Under 35' class for 2023

Lawrence Livermore National Laboratory staff scientist Jeremy Feaster has been named as one of the American Institute for Chemical Engineering’s (AIChE) “35 Under 35” award winners for 2023. The recognition honors chemical engineers under the age of 35 who have made outstanding contributions to their field and to the chemical engineering community, according to the…

Two LLNL scientists selected as 2023 American Physical Society fellows

Lawrence Livermore National Laboratory (LLNL) scientists Manyalibo “Ibo” Matthews and Frank Graziani have been named 2023 American Physical Society (APS) fellows. Matthews was selected from the Forum in Industrial and Applied Physics unit “for pioneering research in optimizing metal 3D printing and laser materials processing.” Frank Graziani was chosen from the Division of…

In a first, LLNL researchers create birefringent all-glass metasurface

Lawrence Livermore National Laboratory (LLNL) researchers have adapted their novel metasurface process, which creates a thin layer on the surface of an optic, to create an all-glass metasurface with birefringence, or dual refraction, properties. This achievement could transform waveplate technology for high-power laser systems such as the National Ignition Facility (NIF)…

PLS postdocs excel at the 2023 Research Slam

On Thursday, August 24, a dozen LLNL postdocs presented in the annual Postdoctoral Research Slam, answering the question “Why is my research important?” in only three minutes. Each talk was then evaluated by LLNL leadership, awarding first and second place to PLS postdocs Brandon Zimmerman and Aditya Prajapati, respectively. As a bonus, the attending audience voted on…

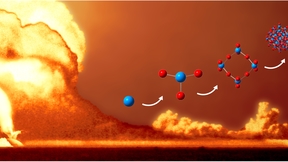

Unlocking gas phase uranium oxidation is key to nuclear debris modeling

In the quest to understand how nuclear debris forms, a team of scientists at Lawrence Livermore National Laboratory (LLNL) has developed an approach to studying the oxidation mechanism of gas phase uranium in extreme environments. In research recently published in Scientific Reports, the team outlined their work, which combined experimental data from a plasma flow reactor …

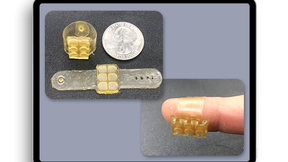

LLNL and Meta engineers develop 3D-printed material with potential for more lifelike wearables

Engineers and chemists at Lawrence Livermore National Laboratory (LLNL) and Meta have developed a new kind of 3D-printed material capable of replicating characteristics of biological tissue, an advancement that could impact the future of “augmented humanity.” In a paper recently published in the journal Matter, LLNL and Meta researchers describe a framework for creating a …

New chemistry leads to more robust carbon capture materials

In a significant stride toward implementing scalable climate solutions, Lawrence Livermore National Laboratory (LLNL) scientists have uncovered how some carbon capture materials have improved lifetime compared to others. These materials are key in addressing greenhouse gas emissions and global warming concerns. Researchers have shed light on the mechanism that empowers…

Breaking down barriers: Sharee Harris shares her career story

A common misconception is that those interested in technical roles at a national laboratory must hold a graduate degree such as a Ph.D. On the contrary, roughly 40% of the science, technology and engineering workforce at Lawrence Livermore National Laboratory (LLNL) claim an associate’s or bachelor’s degree as their highest education level. This false narrative is…

Matter at extremes: a question of scale

Scaling laws are like a secret code used across science to break down complex phenomena into simple mathematical expressions. These equations help us to understand how one factor in a system relates to other factors that determine the system’s behavior. For example, Kleiber’s Law, one of the best-known scaling laws, observes that metabolic rates of many organisms — from…