Back

Advanced Materials and Manufacturing

Putting the pedal to the metal crossing the solid-liquid interface

Most metal alloys are prone to corrosion, which costs hundreds of billions of dollars of damage annually in the U.S. alone. Accurately predicting corrosion rates is a long-standing goal of corrosion science, but these rates depend strongly on the specific operating environment. At the atomic scale, these environmental factors are associated with how quickly and easily…

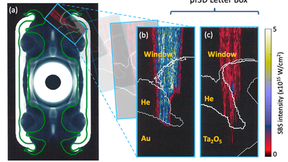

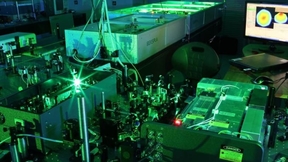

Researchers take closer look at stimulated Brillouin scattering

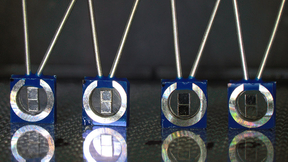

A major cost of running the National Ignition Facility (NIF) is managing and mitigating laser-induced damage to optics as the laser beams propagate to the target. Another damage mechanism stems from stimulated Brillouin scattering (SBS) as light travels back from the target and with nearly the same wavelength as the incoming light. This SBS has the potential to cause…

Two LLNL scientists chosen for 2022 DOE Project Leadership Institute

The Department of Energy (DOE) Project Leadership Institute (PLI) has selected Lawrence Livermore National Laboratory’s Lara Leininger and Al Churby as 2022 cohort participants. Members of the PLI cohort have demonstrated their expertise as technical, business systems or project leaders, with significant experience and responsibility for project or organization performance…

Taking a look at tiny bubbles

The formation and collapse of microscopic bubbles is important in a wide range of fields as both a potential mechanism behind tissue damage, such as in cases of blast-wave-induced traumatic brain injury, and as a useful tool for technology applications, such as mechanical properties evaluation, nanomaterials manipulation and surface cleaning. Nanobubbles have been of…

Capturing microbes in soil and plants

Lawrence Livermore National Laboratory (LLNL) scientists have developed a custom microscope to image microbes in soil and plants at the micrometer scale. Live imaging of microbes in soil would help scientists understand how soil microbial processes occur on the scale of micrometers, where microbial cells interact with minerals, organic matter, plant roots and other…

Two LLNL scientists honored as 2022 Oppenheimer Science and Energy Leadership fellows

The Oppenheimer Science and Energy Leadership Program (OSELP) has selected Lawrence Livermore National Laboratory computer scientist Kathryn Mohror and materials scientist T. Yong Han as 2022 fellows. Established in 2017, OSELP is a distinguished fellowship program that brings together exceptional leaders to explore the complexities, challenges and opportunities facing the…

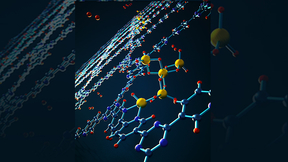

Breaking down the barriers in all solid-state batteries

Solid electrolytes may overcome key technological hurdles associated with the narrow electrochemical and thermal stability of conventional lithium (Li)-ion and sodium (Na)-ion batteries. However, many solid electrolytes — ceramics in particular — also suffer from poor cycling issues and limitations in their ability to efficiently transport ions. These limitations often…

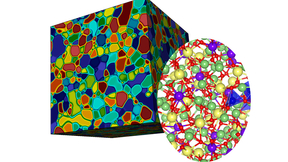

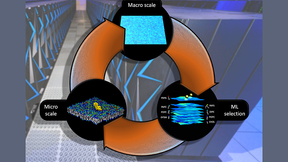

Multiscale simulations of metal additive manufacturing processes

Much of the latent promise of metal additive manufacturing (AM) rests in the potential for controlled creation of spatially tailored microstructures, designed to optimize key build-scale properties through systematic variation across a build. Component optimization possibilities and performance potential expand enormously when this becomes possible. However, the extreme…

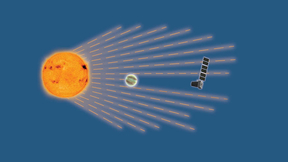

Pandora mission to study stars and exoplanets continues toward flight

The Pandora mission, co-led by a national laboratory and a NASA flight center, has passed a crucial step on its path to study stars and planets outside our solar system, or exoplanets. After a successful concept study report and system requirements review, NASA approved the mission to continue toward flight. Lawrence Livermore National Laboratory (LLNL) and NASA’s Goddard…

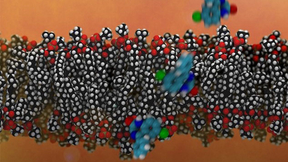

Unprecedented multiscale model of protein behavior linked to cancer-causing mutations

Lawrence Livermore National Laboratory (LLNL) researchers and a multi-institutional team of scientists have developed a highly detailed, machine learning-backed multiscale model revealing the importance of lipids to the signaling dynamics of RAS, a family of proteins whose mutations are linked to numerous cancers. Published by the Proceedings of the National Academy of…

The Path to a Carbon Neutral California

A Livermore report outlines a strategy to reduce California’s carbon emissions to net zero by 2045.

Playing it safe: LLNL scientist creates energetic compounds with isotopic labels

Ana Racoveanu is able to do something most others throughout the nuclear security enterprise cannot do — something challenging and extremely valuable throughout the complex. Racoveanu, a staff scientist in Lawrence Livermore National Laboratory’s Materials Science Division, is able to synthesize energetic compounds with isotopic labels. The primary goal of this work is to…

Disorder in surface materials key to better hydrogen storage

Lawrence Livermore National Laboratory (LLNL) scientists have found that atomic disorder in certain boron-based hydrogen storage systems can potentially improve the rate of hydrogen uptake. Metal boride surfaces and their single-layer variants — known as borophenes — are generally thought to feature a regular arrangement of atoms at low to moderate temperatures. The LLNL…

LLNL researchers garner three awards among top 100 industrial inventions

Lawrence Livermore National Laboratory (LLNL) scientists and engineers have collected three awards among the top 100 industrial inventions worldwide. The trade journal R&D World Magazine announced the winners of the awards, often called the “Oscars of invention,” during a three-day virtual ceremony — Oct. 19-21 — and on the magazine’s website. With this year’s results,…

New hydrogen storage material steps on the gas

Hydrogen is increasingly viewed as essential to a sustainable world energy economy because it can store surplus renewable power, decarbonize transportation and serve as a zero-emission energy carrier. However, conventional high-pressure or cryogenic storage pose significant technical and engineering challenges. To overcome these challenges, Lawrence Livermore National…

Tube-in-tube structure going strong

Similar to grass stems, Lawrence Livermore National Laboratory (LLNL) scientists have created nanostrut-connected tube-in-tubes that enable stronger low-density structural materials. Porous materials with engineered stretching-dominated lattice designs, which offer attractive mechanical properties with ultra-light weight and large surface area for wide-ranging applications…

PLS postdocs battle it out at the 2021 Research Slam!

Lawrence Livermore National Laboratory’s (LLNL’s) fifth annual Research Slam! took place virtually on October 6th and featured 14 LLNL postdocs, 9 of which represented the Physical and Life Sciences Directorate (PLS). Over 300 people logged on to attend the live two-hour event, enthusiastically cheering for their favorite postdocs in the comment section. Each finalist was…

Lawrence Livermore Research Slam! winners advance to Bay Area competition

The top winners of the recent Lawrence Livermore National Laboratory (LLNL) Research Slam!, a speaking competition for postdocs, will advance to the Bay Area Research SLAM set for Thursday, Oct. 28. The Bay Area Research SLAM! is a collaboration between the Bay Area’s national labs (Lawrence Berkeley National Laboratory, LLNL, Sandia National Laboratories and SLAC National…

At the extreme: Breaking the ice mold

New research involving Lawrence Livermore National Laboratory (LLNL) scientists shows that water can remain liquid in a metastable state when transitioning from liquid to a dense form of ice at higher pressures than previously measured. Water at extreme conditions has attracted recent attention because of its complex phase diagram, including superionic ice phases having…

Researchers discover the first nerve-agent antidote that crosses the blood–brain barrier

A team led by LLNL scientists has discovered the first antidote against nerve-agent poisoning that crosses the blood–brain barrier (BBB). Their research, published in Scientific Reports, comes on the heels of a recent resurgence of nerve agents in transnational conflicts. Organophosphorus-based nerve agents (OPNAs)—including sarin, soman, and VX—cross the BBB and are…